Cracker Jack® and the Cummins® ISX engine have something in common – a surprise inside. Looking inside a Cummins ISX to see what surprises you may find could also be considered a treasure hunt… you may find several, or none.

Here is an overview of some of the updates, and a few safety measures that may catch you off guard when repairing or rebuilding Cummins ISX engines.

Cummins ISX engines have been around since the late ’90s and will continue to be produced and needing repairs for the foreseeable future. There have been multiple updates to these engines over the years. The earlier dual camshaft engines have been replaced by the later single camshaft designs.

This article summarizes the major changes with the following ISX engine components: pistons, liners, connecting rods and bearings, and camshaft (single vs. dual).

Early ISX engines used two-piece articulated piston assemblies, but rarely are seen today. More common are the one-piece steel pistons. The skirt design and the crown diameters differ between the one-piece steel pistons. Most of the open skirt pistons are now updated to the closed skirt design. These piston designs cannot be mixed within an engine. An engine should have either all open or all closed skirt pistons. Pistons used in APR (Anti-Polishing Ring) liners have smaller diameter crowns to accommodate for the ARP ring in the liner. Non-APR pistons cannot be used in APR liners.

There have been several design changes to the ISX liners over the years. The 150mm non-APR, 150mm APR, 152mm non-APR and 152mm APR are commonly found in today’s engines. The old grooved top liner and the 150mm without the shim are not as common today. IPD’s innovative “steel” ISX liner is a change in material, and not the design.

When discussing a large bore liner or cylinder block, one typically thinks of the inside diameter of the cylinder and pistons. However, for the ISX/QSX (15 liter) engines, this is not the case. The diameter being referred to is the outside diameter of the liner, and the receiving bore size of the cylinder block {this only pertains to the late style “flat top” liners).

The difference in diameters is only .078″ (2mm), this creates the possibility that unknowingly the smaller 150mm OD liner can be installed into the larger 152mm OD cylinder block. This could allow coolant to enter the oil system, or a catastrophic engine failure since the liner is unsupported. These larger bore cylinder blocks are backwards compatible with previous production blocks but do require some additional parts. The liners are not backwards compatible. Unfortunately, according to a Cummins technical service bulletin, the exact production of engines with the larger bore blocks is not completely clear, and there is a potential that QuickServe (Cummins online program) may list the incorrect block and cylinder liner part numbers. Additionally, if an engine has had the cylinder block, short block, long block, or remanufactured engine replaced, then it could potentially have either the small or large bore cylinder blocks.

Even with the cylinder head and oil pan removed, there is no way to tell these liners apart while they are installed in the block. There is one groove (band) on the non-APR liner, and two grooves (bands) on the APR liner that are visible on the outside bottom of each liner that identifies them as being one of the bronze shim designs, but these grooves do not identify the diameter of the liner. The cylinder block and liner must be measured to assure they are a correct fit.

The design of the bronze shims between these liners are also different. The shim for the 150mm liner has tabs that hold it in position on the liner, as shown below. The shim for the 152mm is larger in diameter and does not have the tabs. The shims are replaceable, but they are not reusable.

The liner seal O-rings are also different in diameter for the 150mm and 152mm liners, but they can be identified by their color. The O-ring for the 150mm liner is pink, and the O-ring for the 152mm is blue.

Non-APR and APR (Anti-Polishing Ring) are references to the design of the top ID areas of the liner. Non-APR liners have the traditional straight ID bore. APR liners feature a removable ring that overhangs the liner bore. The purpose of this APR ring is to remove carbon deposits from the side of the piston crown. This helps prevent bore polishing of the liner walls.

A piston installation tool (#5299339) is required when installing the piston into an APR liner. Remove the APR ring from the liner, insert the installation tool, and then proceed to complete the piston installation. The piston installation tool prevents the piston rings from expanding into the APR ring groove, thus providing a smooth transition of the piston into the cylinder liner.

Block Condition

Block Condition The OE service publication requires the counter bore depth (distance from the surface of the block deck to the counter bore ledge) to be measured in four locations, and the variance between those four measurements cannot be greater than 0.025mm (0.001″), and The ledge must be flat (level) within 0.0127mm (0.0005″).

The condition of the surface of the counter bore ledge is also very important. Machining lines should be visible all the way across and around the entire circumference of the ledge. There should not be any areas of fretting or erosion across the surface, or on the inside or outside of the ledge, as shown below. This ledge (and the dimensions of the liner) is responsible for achieving the correct liner protrusion, and correctly supporting the liner.

If the counter bore height, or if depth variance is greater than is 0.025mm (0.001″) and/or the surface of the counter bore ledge is beyond the reusability guidelines, the block will need to be machined for a repair shim.

There are three different connecting rods designs used in these engines. The early engines used a non-drilled rod, which did not have an oil passage running between the connecting rod bearings

up to the connecting rod bushing. Later engines use drilled connecting rods, of which there are two different types: saw cut and fractured. These terms describe the surfaces between the connecting rod and rod cap. Saw cut rods have been used for years, and fractured rods are the newer technology (released in 2012). Matching the correct connecting rod bearing to the correct rod is critical. Drilled connecting rod bearings must be used with drilled rods. Fractured rods require different bearings from saw cut. Fractured and saw cut connecting rods, however, can be mixed in an engine.

The connecting rod bearings (big end) for the saw cut rods are made up of an upper and lower shell. The shells are marked as to their locations and have alignment tabs that are slightly offset.

Be careful, this design does leave room for error. In most cases where upper and lower shells are involved, the alignment tabs are designed so that the shells cannot be installed incorrectly. In the ISX saw cut connecting rods, the tabs on the bearing shells are only offset approx. 2.89mm (.114″).

Although it is noticeable if the shells are installed incorrectly, the connecting rod can be installed with the bearing shells in the wrong location. There is enough clearance that the rod can be bolted in place to the crankshaft. If this happens, the engine is destined to fail. The bearing will wear on the fillet radius of the crankshaft. Since the lower shell (which is now in the upper position) does not have the oil supply hole in it, then the connecting rod bushing (small end) and piston pin connection fails due to the lack of an oil supply.

Each time the fractured joint is separated small amounts of debris may be produced. The surfaces should be carefully cleaned with solvent and a soft nylon brush; do not use a wire brush or course method when cleaning these surfaces.

A fractured rod can be identified by the small hole on the bottom of the rod cap. A saw cut rod does not have a hole in the cap.

The bearings for the fractured rods also have an upper and lower shell, but the tab design prevents them from being installed incorrectly. The bore diameter (big end) of the fractured connecting rod is larger and the wall thickness of the fractured bearing is thicker, so there is a chance of installing them into a saw cut rod.

If the connecting rod bolts are going to be reused, then they must meet the following criteria:

Attention to some of the smallest details and referring to the latest OE service publications are two key factors in a quality rebuild or repair.

Statistics show that debris (dirt) is the number one cause of bearing failure, which brings us to the first simple precaution. To those not familiar with the ISX engines, the presence of small plugs in the engine and gasket kits may seem odd or perplexing. If the technician does not know their purpose, and/or if discovered after the engine repair, this can lead to confusion.

Over the years, Cummins has had various service campaigns and literature stressing the importance of using these plugs during repairs on ISX engines. Sadly, these plugs are often overlooked.

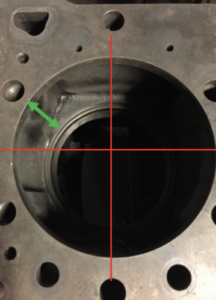

The purpose of these plugs is to temporarily block off the oil ports, thus keeping debris out of the engine while it is being repaired. On the ISX engine, there are almost straight ports from the lower bearings to the upper bushings in each corner of the cylinder block and head. After the cylinder head is removed, these ports become open pathways for debris to enter straight down into the lower oil passages of the engine.

Below is a photo of the front of an ISX block with the plugs (circled in green) installed in the oil ports.

There are two additional ports at the back of the block.

Plugging the ports in each corner of the cylinder head is also important, since debris entering these ports can go directly into the cam and upper bushings.

Of course, there are far more ports and openings to consider on an engine than just where these plugs are used. In fact, there are additional plugs used for the front and sides of the cylinder block. The OE service manuals have more detailed instructions for keeping debris out, and for cleaning and protecting engine components.

While it may be common practice to drive the camshaft bushing in for other engines, Cummins installation instructions indicate that the cam bushings (injector and valve) are to be pressed in (not driven). Several cylinder head rebuilders have reported that they are convinced that due to the size and amount of retention (crush) holding the injector cam bushings in place, they cannot be driven in without distorting or damaging the bushing, resulting in bushing failures.

Common to most assembly instructions and practices, prelubing an engine before startup is not a new practice. In the dual cam ISX engines, the massive injector camshaft receives its oil from the cylinder head at the end journals (#1 and #7). Oil is then supplied to the remaining journals via the large oil port inside the camshaft. This internal oil port holds approximately 1.06 liters (36 oz.) of fluid. That is a capacity of over a quart of oil in this camshaft alone! Considering the load these camshaft bushings carry, the timing for pressurized oil to reach the bushings is critical.

So, what is next? Roll up the air hoses, sweep the shop, clean up the tools, wash your hands, and have a snack before it is time to open the next surprise package.■

Steve Scott joined the service department at lPD in 1982, working with parts, service and sales for a variety of equipment, diesel, and natural gas engines. Since 2004, he has been the director of product development and technical support for lPD. For more information, email sscott@ipdparts.com.

If you’re an existing customer and already have a login, click here to find IPD quality parts.

If you would like to find an IPD distributor or become an IPD distributor, please fill out our form.