“An ounce of prevention is worth a pound of cure.”

— Benjamin Franklin

It’s doubtful that Benjamin Franklin was thinking about a combustion engine when he coined that phase, but it does apply. Considering that a diesel engine could weigh several hundred or thousand pounds, that could add up to a fair amount of prevention. Preventive and proactive maintenance can save you money, extend the life of your equipment, and you can plan it in advance. Most likely everyone has heard the old comedy line, “Doc, it hurts when I do that” — but since engines can’t talk, they may be telling you something is wrong in a different manner.

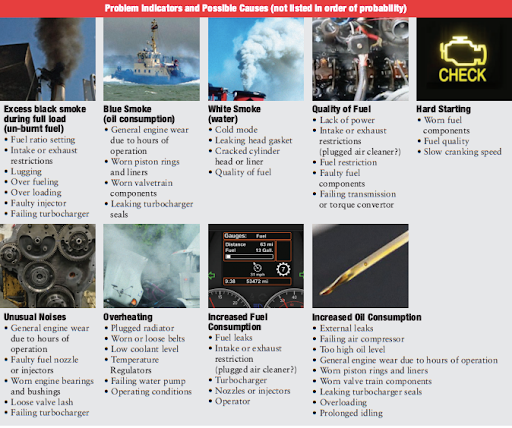

With the variations in diesel engine designs running in equipment today, it is impossible to make a complete list of the symptoms and causes you may encounter. This article will provide you with a general list of possible causes related to some of the more common conditions you may encounter. Of course, indicators and causes will vary between engine models, applications and designs.

As you review the list, you will most likely be able to add and delete information based from your own experiences.

Engines equipped with ECMs (electronic control modules) and the variety of sensors that support those systems can affect many of the indicators listed. Reviewing and understanding those systems and the related fault and error codes can save a tremendous amount of time and expense. Beyond the symptoms and external signs of a problem, the preventative strategy using fluid sampling can be a reliable source of insight on what is happening inside the engine. Oil sampling can help determine trend lines and identify when various components are beginning to fail. These relatively inexpensive tests are like blood tests, but for your engine.

Oil analyses can identify metal from wear, condition of the oil, and any contaminants in the system.

The most important part of an analysis lab report is generally found in the lab’s comments and recommended actions. The report will also include detailed micron size and particle counts, if this information interests you. Element analysis will help identify the source of various metals within the engine.

Depending on the applications and manufacturer, some examples of this are:

Cooling system maintenance and analysis is just as important as oil analysis. Studies have reported that approximately 40% of all premature engine failures are the result of cooling system insufficiencies.

It is the engine owner’s decision as to what level of maintenance program they choose to adopt — proactive, preventative, or the far more expensive post-failure program.

Some opt to use methods that test for potential issues, while some watch and listen for them. Yet, others will wait until the engine shows them there was a problem after it is too late… “Doc, it hurts when I do that.”

Steve Scott joined the service department at lPD in 1982, working with parts, service and sales for a variety of equipment, diesel, and natural gas engines. Since 2004, he has been the director of product development and technical support for lPD. For more information, email sscott@ipdparts.com.

If you’re an existing customer and already have a login, click here to find IPD quality parts.

If you would like to find an IPD distributor or become an IPD distributor, please fill out our form.