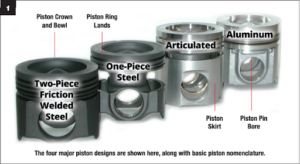

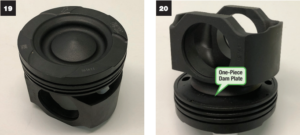

Piston designs have changed in recent years and the design you take out of an engine may not look like the new replacement. If it does not, you certainly need to confirm the replacement is correct before going further with a rebuild. Even greater attention should be applied where the thought of mixing different design pistons within an engine are involved.

The level of the materials and workmanship a manufacturer puts into their products does vary, and those qualities can be difficult to determine. This article

focuses on some of the various design features.

Some pistons have valve pockets (reliefs). The size, depth, and number of pockets depends on the engine applications. Pistons with valve pocket(s) are commonly directional. (Figures 5-6)

A less common feature making a piston directional is an offset pin boss. These can be difficult to identify. Offsetting the pin boss helps compensate for the rotational thrust of the engine. If a directional piston is installed incorrectly, once the head is installed the engine likely will not turn over, but if the engine does startup, it is a safe bet that it will not survive until the first oil change. (Figure 7)

Directional pistons commonly have an arrow or other indicator on the crown. Generally, the arrow points to the front of the engine. (Figure 8) Some indicators on the crown of the piston are simply there to help the installer. This flat crowned piston is not actually directional, but the connecting rods are. This small “V” stamp in the crown is there to help the technician during assembly. The “V” goes on the same side as the numbers and tabs (tang slots) on the connecting rod. (Figures 9-12)

Aluminum pistons could be considered the older of

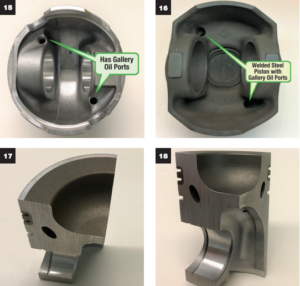

This cutaway of an aluminum piston shows a dual Ni-Insert (described later in this article) and the oil gallery in the piston crown. (Figures 17-18)

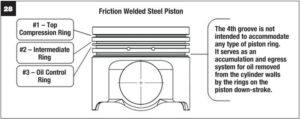

One of the most questioned features involves the various oil drain back designs. The oil ring scraps excess oil from the liner wall on the downward stroke of the piston. To keep the rings from being flooded, the excess oil needs a pathway to escape. Common pathways are drain back holes in the back of the oil ring groove, drain back slotted in the bottom of the oil ring groove, or an egress system.

Oil drain holes allow the excess oil to escape through the oil ring and back into the inside of the piston body. (Figures 21-22)

Drain back slots allow the excess to flow back down the side of the piston. (Figures 23-24)

The accumulation and egress system in the welded steel pistons at first glance may be confused as being a fourth ring groove. This fourth groove serves as a reservoir for the excess oil. Reliefs are machined into the oil ring land allowing oil to accumulate into this reservoir. Of course, how these reliefs are machined also varies. (Figures 25-28)

These inserts are easy to identify. A single Ni- Insert supports only the top compression ring. A dual Ni-Insert supports the top and intermediate rings. (Figures 29-30)

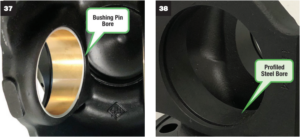

What may appear to be a simple round machined surface is far more complex than it appears. Industrial piston skirts are often barrel shaped, and the surface finish helps hold the protective oil film. Most pistons are also elliptical. The OEM guidelines may list a few dimensional specifications for pistons, but those can also be confusing or misleading since they generally do not specify the exact locations to measure. For example, the outside diameter of the crown can be machined differently than the lands below it, and the lands between the rings may be machined at varying angles. Measuring in the wrong location may result in disqualifying a piston unnecessarily. (Figures 31-32)

Articulated pistons may seem a little odd. The crown of the piston and skirt are held together by the piston pin, but the skirt may not fit tightly against the bottom of the crown. The top of the skirt may have reservoirs or passages to retain oil to help cool the piston crown. Might be silly to mention, but the skirt may be directional (top/bottom). Honestly, I did not know it could happen, but I know of at least one instance where the skirt was installed upside down and it broke off the piston cooling jet (tube) and seized the piston. (Figures 33-34)

The purpose of this article was to take a quick look and address some of the more common questions we hear. All the features shown are in current production pistons today, but this is just an overview. The design details of each could likely be separate articles, but you would likely be as bored trying to read them as I would be writing them. The demand to improve efficiencies, reduce emissions, and extend service life are contributors to some of these changes, but there is not a one design fits all answer. Differences between a used piston and a new replacement does not necessarily mean the new is wrong. The old and new features may or may not be interchangeable or compatible. It is better to ask than take a chance changing designs on your own. Pistons are at the heart of the horsepower, and that is not a good place to have a problem.

Steve Scott joined the service department at lPD in 1982, working with parts, service and sales for a variety of equipment, diesel, and natural gas engines. Since 2004, he has been the director of product development and technical support for lPD. For more information, email sscott@ipdparts.com.

If you’re an existing customer and already have a login, click here to find IPD quality parts.

If you would like to find an IPD distributor or become an IPD distributor, please fill out our form.