If foot pounds of torque were poker chips…

Reuse, research, rethink critical fasteners

There are various criteria for inspection and/or replacement of critical fasteners, and when it comes to cylinder head, connecting rod, main cap, and injector hold-down bolts, it can be confusing. OE Manufacturers often publish general guidelines for reusability, and occasionally will reference a bolt length specification to determine if the bolt is within limits. However, those are only guidelines, and the actual application may call for various bolts to be replaced after each use, or after a specific number of uses. Even more confusing is that some manufacturers or suppliers include critical bolts in their overhaul engine kits or gasket kits, yet others do not. Whether or not a bolt set is included (or not included) in the kit is not a guarantee that a bolt is reusable. Referring to the latest OE service publications is the best resource. Researching this information in advance will help to avoid any unexpected expenses and delays during assembly. Critical fasteners are not necessarily an inexpensive item. A Cat 3500 series head bolt lists for around $24 each. Considering there are eight primary bolts per cylinder head ($24 x 8 = $192), and depending on the design, there can be eight to 24 heads on the engine.

There are various criteria for inspection and/or replacement of critical fasteners, and when it comes to cylinder head, connecting rod, main cap, and injector hold-down bolts, it can be confusing. OE Manufacturers often publish general guidelines for reusability, and occasionally will reference a bolt length specification to determine if the bolt is within limits. However, those are only guidelines, and the actual application may call for various bolts to be replaced after each use, or after a specific number of uses. Even more confusing is that some manufacturers or suppliers include critical bolts in their overhaul engine kits or gasket kits, yet others do not. Whether or not a bolt set is included (or not included) in the kit is not a guarantee that a bolt is reusable. Referring to the latest OE service publications is the best resource. Researching this information in advance will help to avoid any unexpected expenses and delays during assembly. Critical fasteners are not necessarily an inexpensive item. A Cat 3500 series head bolt lists for around $24 each. Considering there are eight primary bolts per cylinder head ($24 x 8 = $192), and depending on the design, there can be eight to 24 heads on the engine.

The highest stress areas of the bolt are the first thread below the shank, the first exposed thread outside of the casting or nut, and the radius below the bolt head.

Even if you are replacing the bolts with new ones, the inspection guidelines are a wise precaution to follow. Damage to the shank, threads, and under side of the bolt head can cause a stress riser, and/or compromise the clamping (torque) force of the bolt.

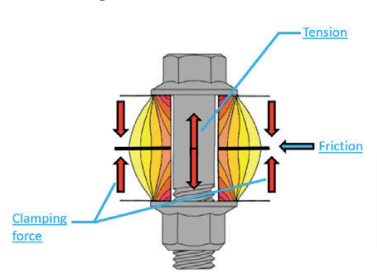

Tightening a bolt creates a cone effect in the clamping force between the two parting surfaces. This force reduces as it moves further away from the bolt. If the bolt is tightened properly, it should only experience a tension (stretching) load. Friction between the two parring surfaces created by the clamping force would carry the heat or bending loads.

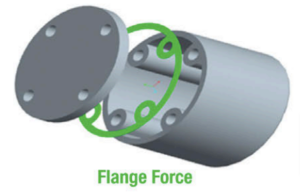

The amount of force that properly tightened bolt(s) apply is amazing. Something as small and simple as a steel flange using four 8mm bolts and tightened to 18.5 lb-fr (24.97Nm) can create over 3500 pounds of ten ion (clamping) force per bolt.

Given:

8mm (.315″) bolt

18.5 ft-lbf of tightening torque

0.2 coefficient of friction (steel on steel)

Where F=T/(c•D):

F= (18.5 ft-lbf/(.2″.315In) “(121nm) = 3524 lbf

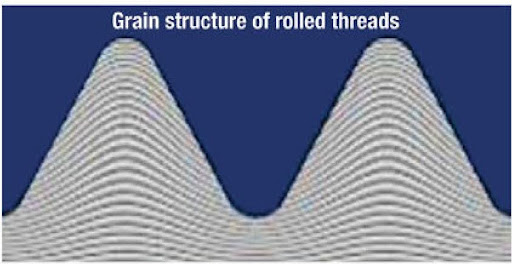

Many of the critical fasteners are made from forged blanks with rolled threads in order for the bolts to withstand the hundreds of pounds of torque, and the top rating forces of the engine. Forging the head on the bolt optimizes the grain structure and increases fatigue life to three times that of a machined bolt.

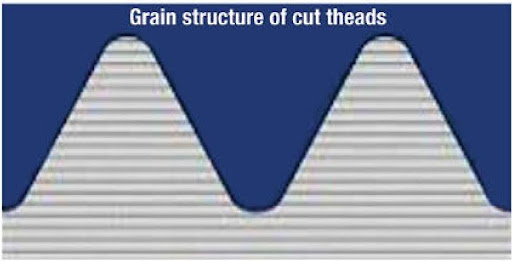

Rolling the threads, as opposed to cutting them, creates continuous unbroken grain lines following the contours and increases the tensile and shear strength.

Two culprits that can have negative effects on the torque values are:

For example: Using 220 (lb-ft) of torque on a 5/8″ diameter bolt M16(10.9)

Using the wrong lubricant could go beyond the bolt’s yield limit.

The method for tightening (torque) bolts varies by OE manufacturers and by application. Here are examples of the torque value and sequence from three manufacturers for head bolts (for reference only).

The 38 head bolts are torqued in four stages:

Tighten the head bolts in sequence:

(One example for the main head bolts)

torque of 4 0″‘ 20 N•m (330″‘ 15 lb-ft)

The science and mathematical calculations that go into determining the torque sequence, value, material, load, and processes are incredibly involved. Altering these values and procedures can have negative effects. Bolts function like a spring (tension) that maintains a constant clamping (crush) force between two surfaces. How the bolt is designed, and consideration for

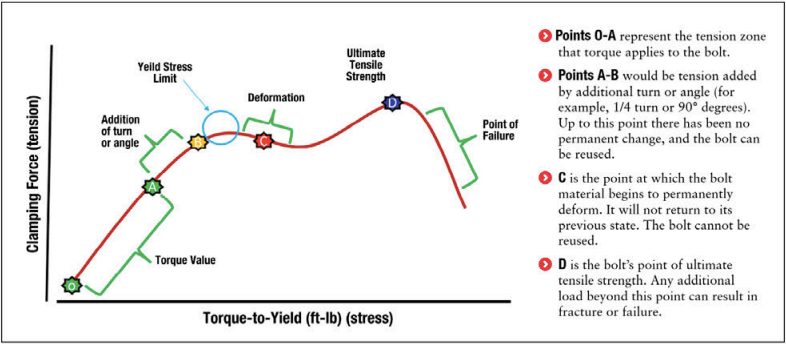

the forces it must withstand, determines if it can be used multiple times, or only once. The torque-to-rum, or torque-to angle procedures help dial in the stress force applied to the bolt. The graph shown above helps illustrate the proportional limit and yield point for a bolt.

Once a bolt passes its yield stress limit, it is permanently compromised and will not return to its previous state. Single technicians are tempted to add additional foot pounds of torque. or degrees of turn (angle), beyond the manufacturer’s specifications. Although added torque may not stretch the bolt past the yield stress limit or ultimate yield point, it may have negative effects on other components (head gaskets, liner flanges, castings, etc.). Once stretched past these critical points, any resulting failure is not the fault of the bolt. Unfortunately, unless the bolt shows signs of damage there is no visible way to tell if it has been compromised.

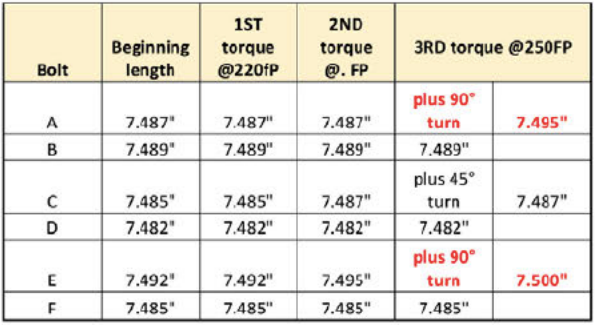

The engineering and manufacturing specifications for a specific bolt can identify the elastic limit and yield points, but to illustrate the physical effects of altering the torque values, we measured the length of six new head bolts for 60 Series Detroit engine, and then applied various torque and torque turn values. The graph shown below displays our findings. After the 1st torque at 220 lb-ft, the bolts measure identical to their beginning length. We repeated this exercise again on these bolts at the same 2ZO lb-ft and found only a slight change in the length for two of the six bolts. For the third test, we increased the torque to 250 lb-fr and added a 45° turn to one bolt, a 90° turn to two of the other bolts. This is the point where we began to find permanent deformation. The bolt with the 250 lb-ft plus the 45• turn was able to return to its original length, but both bolts with the 250 lb-ft plus the 90° rum have reached their point of no return. At some point the addition of the 45° to 90° turn compromised the integrity of these two bolts, resulting in permanent deformation. le is also important to note that there wasn’t visible damage to the bolts.

Although the added foot pounds of torque and additional degrees of turn used in our experiment may be higher than most technicians would add to a given assembly specification, an important point to consider is that the exact limitations for any bolt are seldom known at the time of assembly, and visible inspection may not reveal its structural condition.

A manufacturing process that is becoming more popular in the industrial and heavy-duty diesel industries is cryogenically freezing bolts. This is a process of raking the bolt down to -310°F (-190°C), keeping them at that temperature in liquid nitrogen to remove residual stresses, and then ramping temperature back to room temperature, followed by a mild heat treatment process. The result is up to a 20% increase in yield, longer bolt life, less internal stress and optimized tensile strength.

Another option you may want to consider, depending on the application or component, is studs in place of bolts.

A bolt is subjected to a torsional (twisting) load, a stretching load, as well as frictional loads from under the bolt head and the lunger thread engagement. Studs, however, provide for more accurate torque values since they are subject to axial (stretching) load and less friction from the short thread length of the nut. Studs also offer less wear to the threads in the castings (cylinder blocks, housing, etc.) than bolts. Studs are typically made from high grade materials, finer manufacturing processes and may or may not be cryo treated.

Following the OE manufacturer’s guidelines when it comes to qualifying, assembling, or replacing fasteners is best practice. The cost of the bolts can be substantially less than the cost of the potential damage and second repair due to bolt failure. Is it really worth it?

Gambling without leaving the comfort of your home… Reuse, research, rethink critical fasteners.

Steve Scott joined the service department at lPD in 1982, working with parts, service and sales for a variety of equipment, diesel, and natural gas engines. Since 2004, he has been the director of product development and technical support for lPD. For more information, email sscott@ipdparts.com.

If you’re an existing customer and already have a login, click here to find IPD quality parts.

If you would like to find an IPD distributor or become an IPD distributor, please fill out our form.